Just in case at any point this year you’re sitting around wondering if there’s an inventory adventure you can embark on to help your inventory and your hospital, you’re in the right place. And if you experience a slow point at your hospital, you can use one of these activities to make sure you’re still growing and improving.

6 Inventory Tasks You Can Do While There is Hospital Downtime

1. Get organized for the end of year counts.

As the end of the year inches closer, it’s an important time to start thinking about end of year counts. If you have set up cycle counting, this will make your job so much easier. If not, it’s a great time to start setting them up (read this article to help you get started)! Here are some things to help get you thinking about end of year counts:

- Get your categories in order; make sure they are organized and they actually make sense!

- Plan the logistics; how will you perform the counts? Are you going to close, or count items and update them right away?

- Who is going to help? Is the entire hospital going to be involved (preferred!), or can you delegate anything?

- If other team members are going to be involved, what will their role be? Can you assign people to specific categories?

- When does your accountant need final numbers, or when is the deadline?

- What other tools or plans would be helpful to get your end-of-year counts all completed?

2. Create or revamp a central storage for your hospital.

During times when the “laundry is caught up”, it’s a great time to observe and evaluate your hospital and your inventory to see if things need to be improved. Look at your inventory from a 30,000 foot view; what can be improved? Think about it, do you have an item that’s always disappearing and no one can ever find? Is your central storage a mess, or is it non-existent? Does each item have a specific “home”, or do hospital supplies rotate? Think about how you can develop a more efficient and organize central storage. There are several ways to establish a central storage, but the main objective is to create a “back-up” storage place where overstock of items or a main storage area for hospital supplies.

Once you’ve looked at the bird’s eye view of your inventory, now examine different “trouble” areas of the hospital. Are your muzzles out of control? Do your endotracheal tubes look more like a Goodwill donation box than an organized area of hospital? What about your needle and syringe displays? Take a look around your hospitals and identify any areas that need a major overhaul.

Check out some of my favorite storage solutions, part 1 and part 2Â for organization and storage inspiration.

3. Create a Policy & Procedure or Standard Operating Procedure Manual

While the laundry is caught up it’s always a wonderful idea to create a standard operating procedure and policy manual. You may think that SOP’s are a necessary evil and aren’t helpful in real-world applications. But, nothing is further from the truth!! On that note though, there are BAD standard operating procedures which we want to avoid altogether. Good standard operating procedures can:

- First and foremost; eliminate the “firefighting” so you can truly focus on what’s important. Guidelines and expectations can be set for routine and common procedures, so when the unexpected happens it becomes more efficient

- For example; let’s say that you have a standard operating procedure for checking a client in. Every front desk associate is familiar with this policy and regularly follows it. When an unstable HBC comes in, the front desk team can swiftly and efficiently check the client in without panicking or wondering what steps to be followed.

- Eliminate errors and mistakes

- Ensure consistent results each time the procedure is performed

- Support the goals and the vision of the hospital

- Provide written guidelines and expectations for the entire staff

But, on the flip side BAD standard operating procedures can:

- Cause errors and frustrations

- Increase training and labor costs

- Waste time and money

- Get thrown out the window when it get’s crazy (GOOD standard operating procedures should do the opposite and provide clarity and efficiency in times of increased stress or chaos)

- Detract from the vision and the goals of the hospital

I could go on and on about the benefits of standard operating procedures, but I’ll leave you with the most important points. Let’s say for example, would you fly on a plane where the maintenance crew was “sort of” trained, didn’t use checklists, and everyone did things a different way however they wanted?

Probably not.

Let’s say you found out your surgeon who was going to operate on your child only learned the procedure from his old pal Bob who “told” him how, and didn’t have a clear procedure in mind before operating on your child.

Wouldn’t that make you extremely uncomfortable?

Why should our hospitals operate any differently?

Now that we’ve discussed WHY standard operating procedures, let’s talk about HOW. The first step is to list every task that pertains to inventory management (or your hospital in general) and sort based on importance/urgency. Think: what procedure do you get asked how to do every single day? Then break that into bite-size chunks, and pick anywhere from 2-5+ to write each month. Slowly but surely, you will have a completed manual. Each time you’ve created an SOP the entire staff should be briefed and the SOP should have a set place where it is easily accessible by the entire staff.

If you want something immediate and ready to use, check out the inventory management policy and procedure manual. It’s 99% done for you, and you just need to add a few key pieces of hospital-specific information.

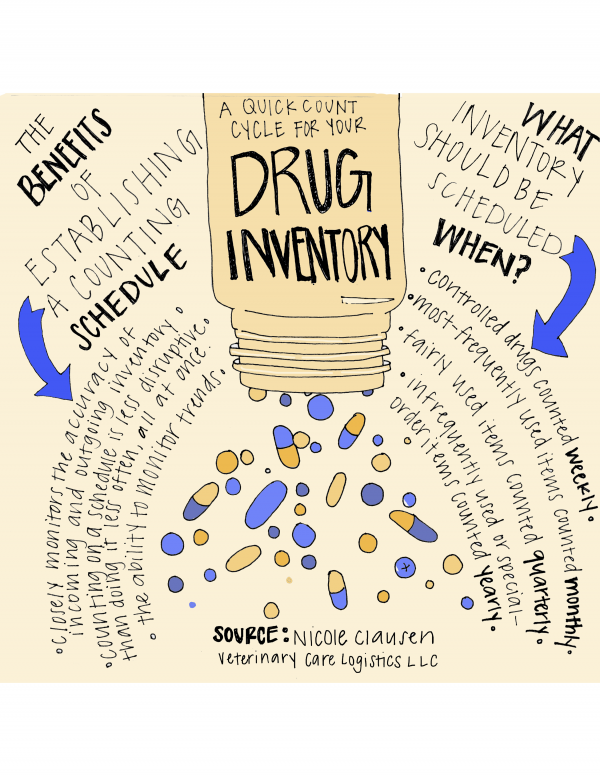

4. Audit and reconcile controlled substance logs.

While you have some extra time on your hand, this is the PERFECT opportunity to have your controlled substances under control. This is an especially important task if you don’t have a system in place or it’s been a while since your last count. I recommend counting and reconciling weekly (every two weeks is okay if your logs are always on).

The biggest source of controlled drug theft I see is with unopened bottles. If you use electronic controlled substance log it is critical that you have some way to track unopened bottles.

If you need help navigating the DEA and controlled substance regulations, check out the downloadable PDF Controlled Substance Guide.

5. Audit prescriptions that have not been picked up by clients.

It seems like almost every hospital has a drawer or hideaway stuffed full of prescriptions that are still pending pick up from clients. It always happens; a prescription is double filled, declined, the husband thought the wife picked it up while the wife thought the husband picked it up. Prescriptions pending pickup are revenue in limbo. The product can’t be sold while it has someone else’s name on it, but it hasn’t yet been paid for. It creates quite the predicament, which is why it’s important to go through those orphaned prescriptions and find out a) if the client still wants the prescription, b) if it’s been paid for, c) if it’s a double-fill and the client already picked up the original prescription.

There are so many possibilities with this prescriptions and the costs can add up very fast. Although it’s great to go through these prescriptions when you have downtime, the ideal situation would be to create a regular schedule to review these and ensure they are not out of control.

6. Check for overstocked products — especially prescription diets.

While you have some extra time, this is the perfect opportunity to review all of your products and ensure that you don’t have overstock, special orders that were never picked up, and/or expired products.

Prescription diets are very expensive to carry and tend to stockpile quickly so while you have spare time it’s an excellent opportunity for monitor and evaluate your diets. There are a couple things you can monitor:

- Do I have any expired or soon to expire product?

- Do I have any forgotten special order products that were never picked up?

- Do I have more than 30 days on hand of an item?

- Is my prescription diet storage organized with clear labels for each product?

- Are there any diets that are no longer selling that I can return for credit?

- Do I need additional food measuring cups, can lids, 6-pack can carriers, or other products that need to be ordered from my representative?

Which “laundry is caught up” activity will you try for your inventory? Please let me know in the comments below. Oh, and, a quick favor: Please share this post with other inventory managers or veterinary professionals you know, so that they can be inspired during lulls in their hospital. Thank you!